GREAT FRIENDS. AMAZING BEER. AND A DAMN GOOD LOOKING SIGN, IF WE DO SAY SO OURSELVES.

ENGINEERS FERRY TOUR OF THE TAPPAN ZEE BRIDGE PROJECT

YESTERDAY THE BUILDING CONTRACTORS ASSOCIATION AND THE CONSTRUCTION ADVANCEMENT INSTITUTE MADE OUR DREAMS COME TRUE! DIRK, ERIC AND ELLIE ATTENDED AN ENGINEER GUIDED TOUR OF THE TAPPAN ZEE BRIDGE PROJECT. BELOW ARE SOME PICTURES AND INTERESTING FACTS WE LEARNED ABOUT THE PROJECT.

- 39 CRANES WERE MOBILIZED AT THE HEIGHT OF THE PROJECT (PUN INTENDED)

- 1,100 - 900 CRAFT WORKERS ARE ON THE JOB DAILY

- 3 CONCRETE PLANTS WERE ON THE JOB, WHICH WILL UTILIZE 200,000 CUBIC YARDS OF CONCRETE NOT INCLUDING PRECAST SECTIONS

- GIRDERS ARE LIFTED IN 350' SECTIONS

THIS PROJECT IS A ONCE IN A LIFETIME EXPERIENCE FOR LOCALS LIKE US, AND GETTING THE INSIDER TOUR OF THE JOB WAS ICING ON THE CAKE!

BIG THANKS TO LAUREL BRUNELLE FOR MAKING THIS ALL POSSIBLE!

LIFTING THE 350' GIRDER S

IN A TWIST OF FATE, WE ACTUALLY WORKED ON THE TOP BRACKETS OF OUR ESCORT BOAT!

FIRST WORK ON THE NEW TAPPAN ZEE BRIDGE

WHK IS PROUD TO ANNOUNCE THAT WE'LL BE BEGINNING OUR FIRST WORK ON THE NEW TAPPAN ZEE BRIDGE PROJECT IN 2016! AS LONG-TIME ROCKLAND COUNTY RESIDENTS, WE'VE BEEN WATCHING THE BRIDGE GO UP WITH AWE. WE'VE BEEN BIDING OUR TIME, WAITING FOR THE RIGHT PROJECT TO CROSS OUR PATH AND IT'S FINALLY HERE!

WHK WILL BE WORKING WITH ANDRON CONSTRUCTION ON THE PERMANENT MAINTENANCE FACILITY DESCRIBED BELOW. WE'RE OVER THE MOON TO BE INVOLVED AND WILL KEEP EVERYONE UPDATED ON THE PROJECT AS IT UNFOLDS.

NEXT GENERATION OF WOMEN BUILDERS

AT WHK, WE'RE VERY FAMILIAR WITH PASSING THE TORCH BETWEEN GENERATIONS. BUT, IT'S EXTRA EXCITING WHEN THE NEXT GENERATION OF BUILDERS IS ACKNOWLEDGED OUTSIDE OF OUR OWN ORGANIZATION.

LAST NIGHT, ELLIE KASSNER RECEIVED THE NEXT GENERATION OF WOMEN BUILDERS AWARD FROM THE WOMEN BUILDER'S COUNCIL. THE EVENT WAS BEAUTIFUL AND PACKED WITH TREMENDOUS INDUSTRY INFLUENCERS.

AS PROJECTS MOUNT UP HERE, WHK IS CONTINUING TO BUILD IT'S LEGACY IN THE NEW YORK METROPOLITAN AREA, BOTH LITERALLY AND FIGURATIVELY.

LRC / GRACE EPISCOPAL CHURCH PARK IN DOWNTOWN WHITE PLAINS

LAST YEAR DIRK WORKED ON THIS PARK PROJECT WITH OUR OLD COMRADES AT LRC CONSTRUCTION. THE FENCE WAS MADE TO MATCH GRACE CHURCH'S HISTORICAL DESIGN, AND THE BENCHES ADDED A NEW AGE TWIST. WHAT A STUNNER!

WECONNECT MENTORSHIP PROGRAM

ENTREPRENEURSHIP IS AN AMAZING AND REWARDING ENDEAVOR, BUT CAN BE ISOLATING WITHOUT A COMMUNITY TO WORK WITHIN. WITH THE MISSION OF CREATING A COMMUNITY FOR WOMEN ENTREPRENEURS, NEW YORK CITY SMALL BUSINESS SERVICES HAS LAUNCHED AN AMAZING NEW PROGRAM, WENYC. BASED ON A COMPREHENSIVE STUDY, NYC SBS HAS CRAFTED A GROUNDBREAKING PROGRAM TO CONNECT WOMEN ENTREPRENEURS, AND HELP US MAXIMIZE OUR EARNING POTENTIAL VIA DEDICATED RESOURCES. ONE RESOURCE IS THE WECONNECT PROGRAM, IN WHICH 17 SUCCESSFUL BUSINESS OWNERS WERE CHOSEN TO SHARE THEIR EXPERIENCES WITH OTHERS.

AT W.H. KASSNER, INC., WE ARE PROUD TO ANNOUNCE THAT OUR OWN PRESIDENT, ELLIE KASSNER, HAS BEEN SELECTED FOR THE PILOT MENTOR PROGRAM! WHEN ASKED ABOUT THE PROGRAM ELLIE SAID, "I'M SO INSPIRED BY THE OTHER MENTORS. I'M HONORED TO HAVE BEEN CHOSEN. BUT MOST OF ALL I'M THRILLED TO SHARE MY STORY, AND THE STORY OF WHK, AND GIVE BACK TO OTHERS." WE COULDN'T HAVE SAID IT BETTER.

MTA SMALL BUSINESS MENTORSHIP PROGRAM

IN NO SMALL FEAT, W.H. KASSNER, INC. WAS JUST ACCEPTED IN TO THE METROPOLITAN TRANSIT AUTHORITY'S SMALL BUSINESS MENTORSHIP PROGRAM! THE PROGRAM OFFERS SMALLER CONTRACTORS THE OPPORTUNITY TO WORK WITH THE MTA AT A GREATER CAPACITY THAN THEY MIGHT BE ABLE TO MANAGE ON THEIR OWN. THROUGH GUIDANCE AND SPECIAL BID OFFERS, COMPANIES LIKE WHK WILL BE ABLE TO WORK WITH THE MTA AND CONTROL OUR OWN DESTINY ALL AT ONCE! WE CAN'T WAIT TO START WORKING TOGETHER!

CHECK OUT OUR NEW FAVORITE THING

CHECK OUT ONE OF OUR NEW FAVORITE THINGS! WE RECENTLY GOT TURNED ON TO THE DISTANCE, A PODCAST THAT COVERS THE HISTORY AND STAYING POWER OF COMPANIES THAT HAVE BEEN IN BUSINESS FOR OVER 25 YEARS.

LISTENING THROUGH, IT SEEMS LIKE WE'RE IN GOOD COMPANY! ENJOY!

THE BUY AMERICAN ACT

OVER THE PAST FEW YEARS WE’VE NOTICED A SIGNIFICANT TREND TOWARDS FABRICATION COMPLIANCE WITH AMERICAN IRON AND STEEL PROVISION, ESPECIALLY ON PUBLIC WORKS PROJECTS. THE REQUIREMENT, COLLOQUIALLY REFERRED TO AS “BUY AMERICAN,” ENSURES THAT FABRICATORS USE IRON AND STEEL PRODUCTS THAT ARE PRODUCED IN THE UNITED STATES. WHEN DELIVERING THE METAL FABRICATIONS, THE FABRICATOR IS ALSO RESPONSIBLE FOR SUBMITTING MILL CERTIFICATIONS DOCUMENTING THE AMERICAN ORIGINS OF THE METAL.

(FOR MORE DETAILED INFORMATION YOU SHOULD CHECK OUT THIS ARTICLE WRITTEN BY LAWYERS.)

NOT ONLY DOES THE AIS REQUIREMENT WORK TO STIMULATE THE U.S. ECONOMY, BUT IT ALSO GUARANTEES AN ELEVATED QUALITY OF MATERIAL USED ON A PROJECT.

THE BALD EAGLES ARE BACK...

... AND THEY'RE BETTER THAN EVER!

EVERY YEAR DOWN HERE BY THE WATER, THE BALD EAGLES SET UP THEIR WINTER HOME. THEY FISH IN THE RIVER, AND HEAD BACK NORTH IN THE SPRING.

I GUESS THEY DON'T MIND THE IRON WORKING NOISE! WHEN YOU VISIT THE SHOP, KEEP YOUR EYES PEELED!

HAPPY HOLIDAYS!

HAPPY HOLIDAYS FROM US AND OURS TO YOU AND YOURS!

WE APPRECIATE EVERYONE THAT MADE OUR PROJECTS SUCCESSFUL THIS YEAR, INCLUDING OUR EMPLOYEES, GENERAL CONTRACTORS, END USERS, MUNICIPALITIES, SUPPLIERS AND VENDORS, AND LOOK FORWARD TO AN EXCITING 2016!

THIS PICTURE WASN'T EVEN STAGED!

THESE PICTURES WERE TOTALLY STAGED...

RESOURCES

BEING TRULY PASSIONATE ABOUT WHAT YOU DO MEANS YOU'RE ALWAYS LEARNING. HERE AT WHK, WE LEARN FROM OUR PAST GENERATIONS, OUR SUCCESS, OUR MISTAKES, OUR CLIENTS AND SUPPLIERS, AND OUTSIDE SOURCES. BELOW ARE SOME OF OUR FAVORITE SOURCES FOR STAYING IN TUNE WITH CONSTRUCTION INDUSTRY TRENDS :

AMERICAN INSTITUTE OF STEEL CONSTRUCTION (AISC) : AISCs EXTENSIVE LIBRARY COVERS EVERYTHING FROM BUILDING CODE REQUIREMENTS TO NEW TECHNOLOGICAL ADVANCES AND APPLICATIONS FOR FABRICATION.

INTERNATIONAL ASSOCIATION OF BRIDGE, STRUCTURAL, ORNAMENTAL, AND REINFORCING IRONWORKERS (IW) : OUR INTERNATIONAL ASSOCIATION OF IRONWORKERS OFFERS GREAT SPECIFIC TRADE INFORMATION IN THEIR MAGAZINE. THE IRONWORKER MAGAZINE CONNECTS TRADESMEN, UNIONS, AND INDUSTRY PROFESSIONALS AND INFORM US OF NOTABLE PROJECTS, TRENDS AND UPCOMING LEGISLATION. (REMEMBER, THE PERSONAL IS POLITICAL!)

WOMEN BUILDERS COUNCIL (WBC) : THE WOMEN BUILDERS COUNCIL NOT ONLY UNITES WOMEN CONSTRUCTION PROFESSIONALS IN THE NEW YORK METROPOLITAN AREA, BUT ALSO STAYS AT THE FOREFRONT OF COMMUNICATING MWBE GOVERNMENT REGULATIONS.

CLASS CENTRAL : WHILE THE INTERNET IS FULL OF USELESS KNOWLEDGE (CAT VIDEOS ANYONE?), ONE OF IT'S BEST KEPT SECRETS IS MASSIVE OPEN ONLINE COURSES (MOOCs). THESE FREE COURSES, MOST OF WHICH ARE SELF PACED, GIVE YOU ACCESS TO BASIC ENGINEERING CLASSES, OR, OUR FAVORITE, STEEL 101. MANY OF THE CLASSES ARE DESIGNED BY HARVARD, MIT AND STANFORD. TAKING A MOOC MAY NOT GET YOU A P.E. STAMP, BUT IT DOES HELP YOU GROW YOUR KNOWLEDGE OF THE INDUSTRY, UPSTREAM AND DOWNSTREAM OF YOUR TRADE.

FORBES ENTREPRENEUR AND HARVARD BUSINESS REVIEW : ALTHOUGH THESE RESOURCES AREN'T NECESSARILY CONSTRUCTION SPECIFIC, THEY DO OFFER SOME GREAT ADVICE ABOUT RUNNING YOUR BUSINESS. BECAUSE THE CONSTRUCTION INDUSTRY IS SO UNIQUE, IT CAN BECOME INSULAR AND, UNFORTUNATELY, KEEP US FROM STAYING CURRENT ON IMPLEMENTING BETTER BUSINESS PRACTICES.

WE HOPE YOU ENJOY OUR FAVORITE SITES, AND BE SURE TO SHARE YOUR OWN!

PASSIVATING STAINLESS STEEL

A SENIOR STEEL ESTIMATOR AT ONE OF THE LARGEST CONSTRUCTION COMPANIES IN THE THE WORLD ONCE TOLD ME THAT HE COULD TELL IF SOMEONE WAS THE REAL DEAL FROM WHAT THEY KNEW ABOUT PASSIVATING STAINLESS STEEL.

AT WHK, WE'RE CERTAINLY THE REAL DEAL, SO HERE GOES!

STAINLESS STEEL IS STAINLESS BECAUSE OF PROTECTIVE CHROMIUM OXIDES ON THE SURFACE OF THE MATERIAL. WHETHER AT THE ORIGINAL MILL, THE SUPPLIER OR THE FABRICATION SHOP, STAINLESS STEEL CAN BE SCRATCHED, PITTED OR OTHERWISE EXPOSED IN THE COURSE OF NORMAL PROCESSING. THIS EXPOSURE OF IRON CAN ALLOW FOR RUST TO FORM. PASSIVATING STAINLESS STEEL WORKS TO COUNTERACT THAT EXPOSURE.

THE MOST COMMON AND PROFESSIONAL PROCESS INVOLVES CLEANING THE STEEL WITH NITRIC ACID, WHICH CLEANS THE STEEL AND SERVES AS AN OXIDIZING AGENT. ALTERNATIVELY, STRONG CONCENTRATIONS OF CITRIC ACID CAN BE USED TO PASSIVATE THE STAINLESS STEEL. BY REMOVING FREE IRON AND OTHER CONTAMINANTS FROM THE SURFACE OF THE STAINLESS, THE CHROMIUM IS REOXIDIZED.

FUN FACT : LITTERED AROUND OUR WEBSITES YOU MAY HAVE FOUND SOME REFERENCES TO BREWING AND DRINKING ALCOHOL. CONVERSATIONS ON PASSIVATING STAINLESS STEEL ARE SOMETIMES PART OF BREWERS FORUMS BECAUSE MANY BREWERS USE STAINLESS STEEL VESSELS, WHICH CAN SOMETIMES BEGIN RUSTING DUE TO EXPOSURE TO CLEANING CHEMICALS.

GIVING BACK

BEFORE

WHK HAS CALLED ROCKLAND COUNTY ITS HOME FOR OVER 40 YEARS. THAT'S WHY WHEN WE WERE APPROACHED BY THE STONY POINT HISTORICAL SOCIETY TO CONTRIBUTE TO THE RESTORATION OF THE PYNGYP SCHOOLHOUSE, WE WERE HAPPY TO BE INVOLVED! WE DESIGNED THE RAILINGS TO CURRENT CODE, WHILE TRYING TO REPLICATE AN ORIGINAL STYLE.

AFTER

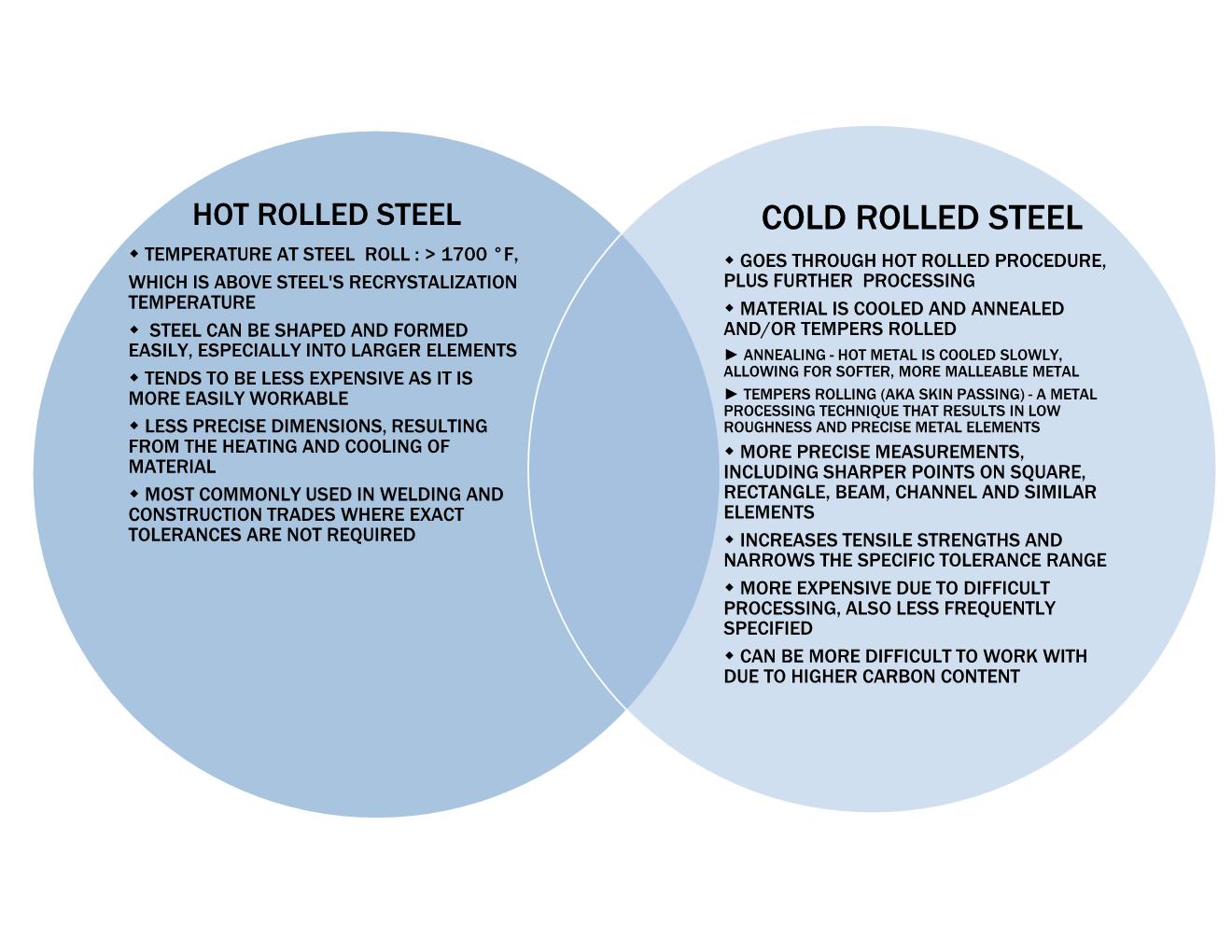

HOT ROLLED STEEL VS COLD ROLLED STEEL

IF YOU HAVEN'T FIGURED THIS OUT YET, I'LL GIVE YOU A HINT : AT WHK WE LOVE WHAT WE DO! PART OF THAT LOVE COMES FROM A GENUINE INTEREST IN OUR FIELD, FROM THE GENERAL TO THE NITTY-GRITTY.

WHILE WE MOST CONSTRUCTION APPLICATIONS CALL FOR HOT ROLLED STEEL, SOME SPECIAL PROJECTS REQUIRE COLD ROLLED STEEL. CHECK OUT THE VISUAL BELOW OUTLINING THE BASIC DIFFERENCES. ENJOY!

THE TRIFECTA : IRONWORK, ART AND BEER

IT'S COMMON KNOWLEDGE THAT THE BEST IRONWORKERS ARE ALSO EXPERT BEER DRINKERS. AMBULANCE BREWHOUSE ASKED US TO MIX BUSINESS WITH PLEASURE BY DESIGNING AND FABRICATING A CUSTOM ARCHWAY. WE OBLIGED WITH A HOP-CENTRIC FOCAL PIECE - AND THE BEER WAS DELICIOUS TOO. CHEERS!

TEKLA 3D MODELING SOFTWARE

WHEN YOU WORK IN A FIELD THAT LITERALLY HAS THE WORD "MISCELLANEOUS" IN THE TITLE, SOME PEOPLE NEED CLARIFICATION : WHAT EXACTLY DO YOU DO? WHILE OUR CAPABILITIES STATEMENT COVERS THE BASICS, WE USE THE 3D MODELING SOFTWARE, TEKLA, TO ILLUSTRATE THE DETAILS.

USING TEKLA IN-HOUSE, WHK IS ABLE TO GENERATE 2D AUTOCAD FORMAT DRAWINGS, ALONG WITH 3D ISOMETRIC DRAWINGS AND OUR SHOP FABRICATION DRAWINGS IN ONE GO. NOT ONLY DOES THIS WORK TO STREAMLINE OUR PROCESSES, BUT IT'S STRONGEST ATTRIBUTE IS THAT IT ALLOWS THE CUSTOMER TO HAVE A CLEAR VIEW OF WHAT THEY'RE ORDERING.

ONE OF OUR BEST EXAMPLES OF THIS OCCURRED A FEW YEARS AGO WITH A MAJOR PHARMACEUTICAL CLIENT. THROUGHOUT A PROJECT, WE WERE NARROWING IN THE DIMENSIONS AND FEATURES OF A STAINLESS STEEL PLATFORM. HOWEVER, DURING THE APPROVAL SIGN OFF, THE SCIENTISTS WERE CONSULTED. UPON SEEING THE 3D DRAWINGS THEY NOTICED FUNCTIONALITY ISSUES WITH THE WAY THEY WANTED TO USE THE APPLICATION. HAVING SEEN ONLY 2D DRAWINGS UP TO THAT POINT, WHICH THEY DIDN'T FULLY UNDERSTAND, THERE HAD BEEN MISCOMMUNICATION. LUCKILY, SINCE FABRICATION HAD NOT STARTED, WE WERE ABLE TO REWORK THE PLATFORM TO MEET THEIR NEEDS SAVING THE PROJECT BOTH TIME AND MONEY.

ANOTHER ONE : NYC WBE CERTIFICATION

WHK IS PROUD TO ANNOUNCE THAT WE'VE RECENTLY BEEN CERTIFIED AS A WBE IN NEW YORK CITY!

(CERTIFICATE MWCERT2015-610).

TYPICALLY, WHK PERFORMS FABRICATION ONLY PROJECTS IN NYC, BUT WE MAY TAKE ON A SPECIFIC PROJECTS SO BE SURE TO CHECK IN!

HOT DIP GALVANIZING

AFTER FABRICATION, IN CONJUNCTION WITH SOME OF OUR TRUSTED SUBCONTRACTORS, WHK HAS THE ABILITY TO PROVIDE MANY FINISHES. ONE OF THE

MOST COMMON FINISHES WE UTILIZE IS

HOT DIP GALVANIZING.

HOT DIP GALVANIZING IS THE PROCESS OF DIPPING FABRICATED STEEL INTO A VAT OF MOLTEN ZINC. IT IS A CORROSION PROTECTION METHOD USED MOST FREQUENTLY ON APPLICATIONS THAT WILL BE EXPOSED TO WEATHER OR WET ENVIRONMENTS. HOT DIP GALVANIZING APPEARS AS A DULL GREY FINISH.

BECAUSE HOT DIP GALVANIZING PROTECTS STEEL, THE WORK MUST BE FABRICATED FIRST (I.E. STAIRS, RAILINGS, CANOPY), THEN HOT DIP GALVANIZED. WELDS OR CUTS THAT OCCUR AFTER THE GALVANIZED FINISH HAS BEEN APPLIED MUST RECEIVE COLD GALVANIZING (ZRC) PAINT AT THOSE JOINTS FOR PROTECTION.

THIS IS THE MOST BASIC OVERVIEW AND THERE ARE MANY INTRICACIES TO THIS PROCESS! FOLLOW THE LINKS OR REACH OUT TO US WITH MORE QUESTIONS ABOUT HOW HOT DIP GALVANIZING WORKS AND WHAT TYPES OF APPLICATIONS MAY REQUIRE HDG.

STEPS IN THE HOT DIP GALVANIZING PROCESS :

- CLEAN THE STEEL, WITH A CAUSTIC SOLUTION TO REMOVE OIL, GREASE, DIRT, PAINT OR BASIC OXIDATION.

- RINSE OFF THE CAUSTIC SOLUTION.

- REMOVE MILL SCALE, VIA ACIDIC SOLUTION.

- RINSE OFF ACIDIC SOLUTION.

- ZINC AMMONIUM CHLORIDE (CALLED FLUX) IS APPLIED TO STEEL TO STOP OXIDATION OF CLEANED SURFACE WHEN EXPOSED TO AIR.

- STEEL DIPPED IN VAT OF MOLTEN ZINC AND HELD UNTIL TEMPERATURE OF STEEL REACHES THAT OF THE BATH.

- STEEL IS COOLED IN A SEPARATE TANK TO INHIBIT UNDESIRABLE REACTIONS THAT MAY OCCUR IF NEW FINISH IS EXPOSED TO ATMOSPHERE WHILE COOLING.

MAKING WBE WAVES

OVER THE PAST FEW YEARS AS WHK HAS TRANSITIONED FROM SECOND TO THIRD GENERATION AND RECEIVED IT'S WBE CERTIFICATIONS, WE'VE BEEN GETTING NOTICED! CHECK OUT SOME OF THE ARTICLES HIGHLIGHTING OUR COMPANY!

REDC / PTAC : SUCCESS STORIES : W.H. KASSNER, INC.

WE USA : TUCK-WBENC EXECUTIVE PROGRAM

WBENC PRESIDENT'S REPORT : 2014 TUCK-WBENC EXECUTIVE PROGRAM